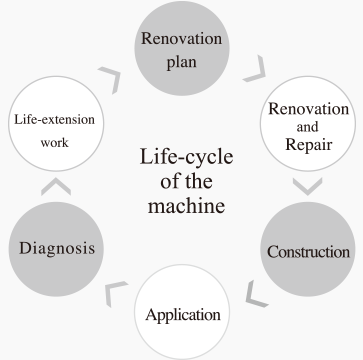

To maintain the stable operational performance of a machine, we give exclusive maintenance service for each part of machine.

By giving the appropriate maintenance according to the remaining service life of each part of a machine, we can maintain

high-performing highly accurate highly reliable

testing equipment.

We will dispatch our engineers who have a good knowledge of diagnosing machines and software as a whole, and we will propose ideas to our customers promptly and meet their needs.

The stable operation of testing or production equipment is an essential and important factor in the manufacturing processes.We construct the most appropriate maintenance control system at a minimum cost by doing prediction/prevention of age degradation, etc. at an early stage.

We calibrate measuring circuits of equipment using a measurement standard device with a traceability based on the national standards and applying the solid calibration technology.

We will help make the best use of the existing assets, by responding to the requests such as the renewal of existing equipment while utilizing its functions, or by utilizing the know-how of the customers’ employees for the existing equipment.

By doing maintenance on the equipment according to the time-base standards, it will help secure safety for operators and factories thus contributing to productivity.

We take prompt actions to repair equipment or solve problems in case of a breakdown of equipment.